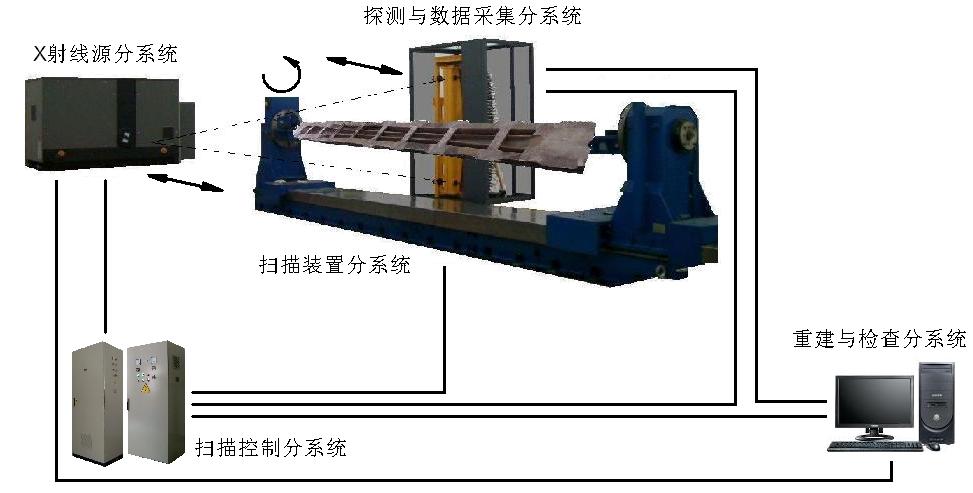

TZ1001 high-energy X-ray industrial DR/CT rapid inspection system

System Overview:

The TZ1001 high-energy X-ray industrial DR/CT rapid detection system uses 9MeV high-energy electron linear accelerator as the radiation source, and the high-precision CT scanning mechanical system completes the scanning movement. The data is completed by the CdWO4 crystal line array detector and the wide dynamic range low-noise electronics system After collecting, data conversion and processing, the DR image and tomographic image of the detected workpiece are reconstructed.

System principle:

The ray source generates fan-shaped high-energy X-rays in a controlled state; the X-rays are attenuated after penetrating the workpiece to be inspected, and the different attenuation levels reflect the internal information of the workpiece; the detector and subsequent systems accept X-rays and convert them into digital signals; In the DR scanning process, the overall projection data is obtained through the translation of the workpiece. In the CT scanning process, the projection data is obtained from multiple angles through the rotation of the workpiece; the acquired projection data is processed and reconstructed to obtain the DR/CT digital image .

Scanning mode: three-generation CT scan, DR scan, film photography

Main performance indicators:

1. Detection efficiency:

Annual inspection volume: more than 8500 pieces (cross, the longest workpiece is 9m long).

2. Detecting workpiece range:

Inspection object: railway line frog; other types of products;

Maximum diameter: 1200mm;

Maximum length: 9500mm;

The maximum weight of the workpiece: 2000kg.

3. Three-generation CT scan:

Spatial resolution: ≥1.5 lp/mm;

Density resolution: ≤0.5%;

CT scan time: ≤1min (1024×1024);

CT reconstruction time: ≤3s (1024×1024;

Reconstruction image matrix: 512×512 ~ 4096×4096;

Crack detection capability: 0.2mm (width) × 10mm (length) × 2mm (depth).

4. DR scan:

Circular defect recognition ability: pores ≤Φ1.0 mm (physical sample);

Sensitivity of DR image quality indicator: ≤1.0% (silk image quality indicator, 200mm equivalent steel);

A single workpiece (9 meters in length) is tested in a single time, and the pixel matrix of equal proportion: not less than 1024×10000;

The single highest DR scanning speed: ≥ 10m/min.